5 Bandsaw Blades (Bahco Sandcut Solid) for Logosol B1001, 4310x33x1.1 mm

| Blade thickness | 1.1 mm |

|---|---|

| Blade quality | Bahco Sandcut Solid |

| Blade for | LOGOSOL B1001 |

| Blade length | 4310 mm |

| Blade width | 33 mm |

| Weight | 1.4 kg |

![]() Hungary

Hungary

Creating an account has many benefits: check out faster, keep more than one address, track orders and more.

Our cheapest bandsaw blade still has fabulous quality. In fact, many people would call it a premium blade. We recommend it for cutting small quantities of wood. You can expect to sharpen it more often than an HSS blade. Many customers choose this blade when they need to cut wood that may have nails in it, as it is easy to sharpen and should it break, the replacement cost is low.

This blade can be sharpened up to 10 times. Easiest done with the Logosol Grindlux band saw blade grinding robot.

| Technical data | |

|---|---|

| Sawblade thickness: | 1.1 mm |

| Saw track: | 2.16 |

| Cutting angle: | 10/30 |

| Saw blade quality: | Bahco Sandcut Solid |

| Saw blade for: | All Logosol band sawmills |

| Saw blade width: | 33 mm |

Important: Do not remove the guard until the blade is installed in the bandsaw.

Sharpening: May be sharpened. If you remove 0.1 mm material each time, you can sharpen the belt around 10 times. Although the blade can be sharpened up to 10 times, we recommend sharpening the blade 3-5 times before replacing it for best results.

Operating time: Economical bandsaw blade if you are prepared to sharpen a little more often, around every 1-2 operating hours. An operating hour refers to the time the blade actually spends sawing. A saw speed of e.g. 0.1 m/sec equates to 360 running metres per operating hour. Thus a blade that lasts for two operating hours will cut around 700 running metres during this time.

Capacity: Easily handles all types of wood, from softwood to hardwood. Works equally as well in winter and summer.

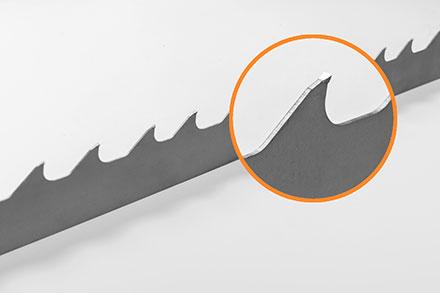

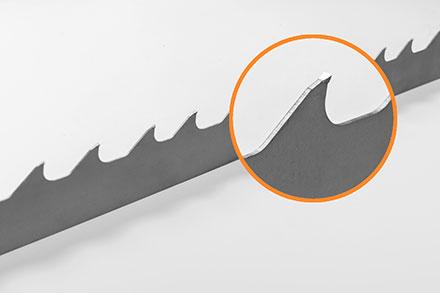

Characteristics: Hardened spring steel blades provide an excellent performance-to-cost ratio. Very high resistance to wear and torsional forces. Specially designed tooth shape for maximum performance.

Caring: No tooth side-setting necessary during blade lifetime.

Tooth of hard metal

| Blade thickness | 1.1 mm |

|---|---|

| Blade quality | Bahco Sandcut Solid |

| Blade for | LOGOSOL B1001 |

| Blade length | 4310 mm |

| Blade width | 33 mm |

| Weight | 1.4 kg |

![]() Hungary

Hungary

For centuries, Sweden has been world-famous for its inventors, design innovations, and high quality of products. The zip, the ball bearing, the gas stove and the monkey wrench are all samples of Swedish inventions that have become indispensible in our everyday lives. Swedish companies such as Ericsson, Volvo, SAAB, Nobel and IKEA are associated with ingenuity, perfection and high standard.

"Made In Sweden" means high quality, innovation and sustainable solutions. Logosol is a Swedish company that really can live up to the expectations! For the last twenty years, innovation, originality, simplicity and quality have been the distinguishing features of our product line. With these features as a basis, Logosol has developed a wide range of equipment for wood processing and woodworking. Due to our products, Logosol has become well-known in this field all over the world.