PK1500 Stack Cutter

Efficient cutting at an unbeatable price

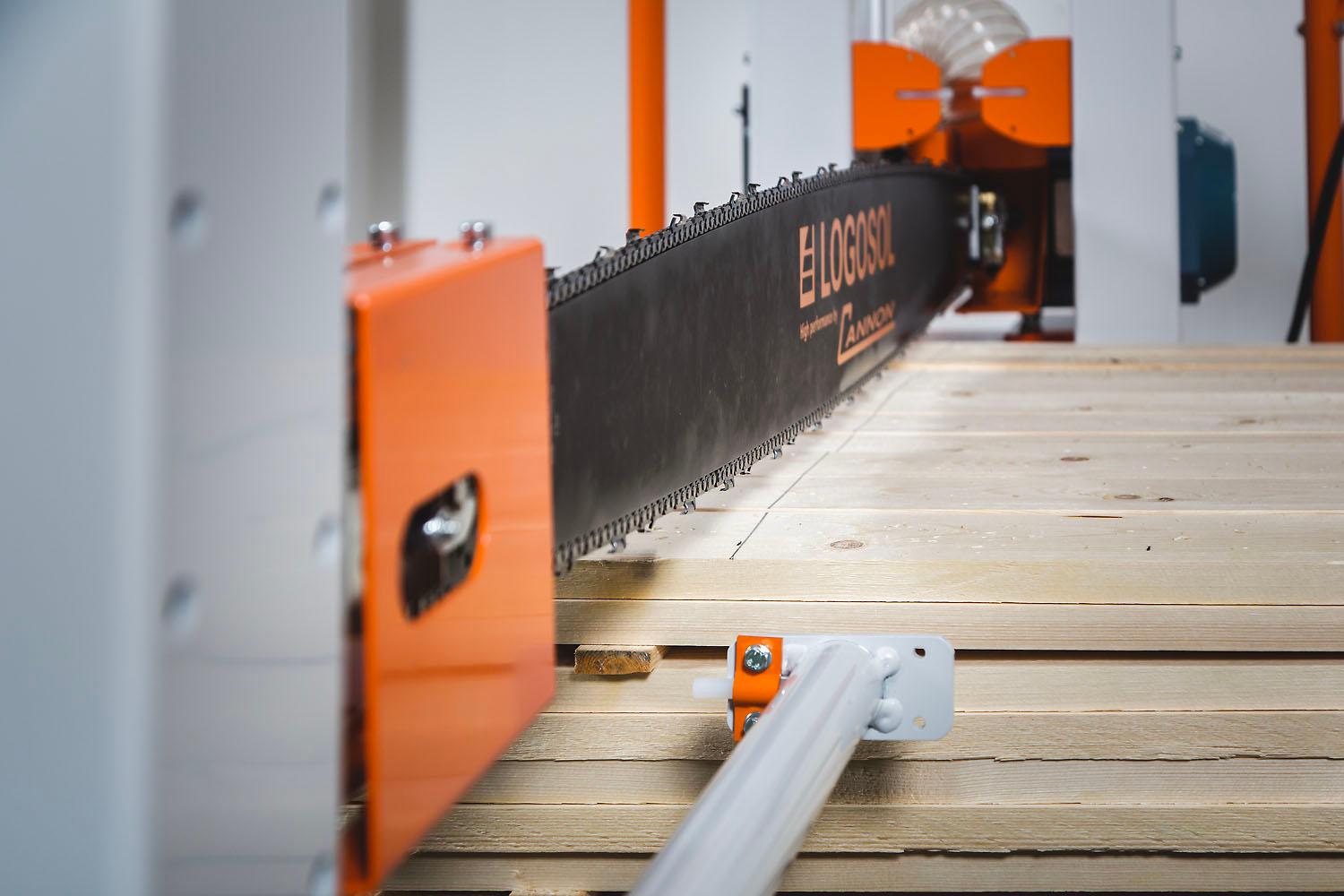

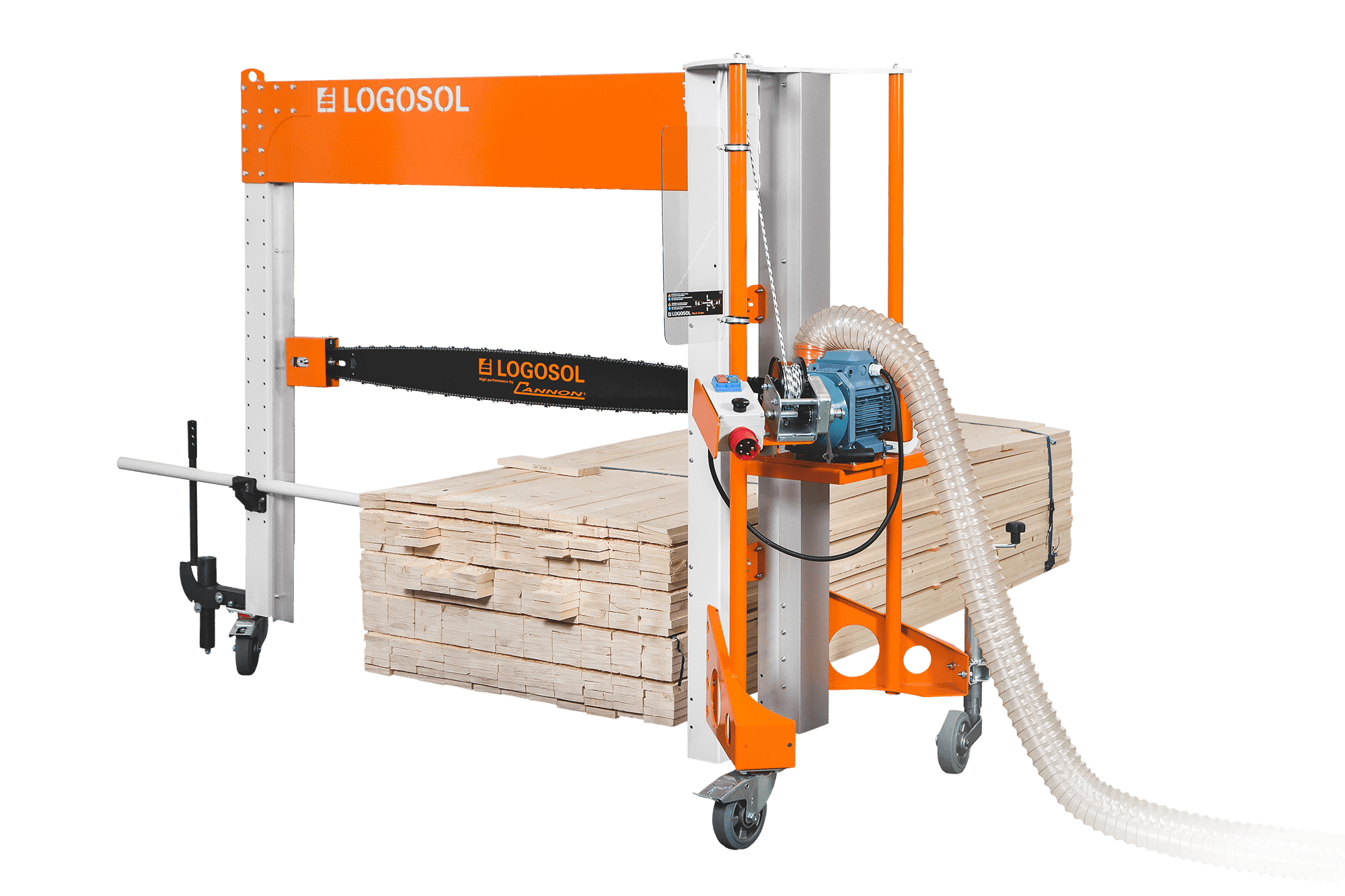

With LOGOSOL’s stack cutter you cut the whole timber stack at once. Just adjust it to the desired length and let the stack cutter do the job — quickly and efficiently with an accuracy down to +/- 2 millimetres. The stack cutter takes the cut linearly vertically, a method that gives you increased capacity and flexibility. This machine is already appreciated by many who cut timber stacks. The 168 cm (66 inch) long guide bar is guided at the bar nose. The chain is a standard cross-cutting chain driven by a strong electric motor. The stack cutter does not take up a great deal of space, and it runs easily on its sturdy castors. The included measuring rod helps you measure the length of the stack. Many simple stack cutters fold the guide bar down through the timber stack. Vertical cutting is used by LOGOSOL’s stack cutter and by significantly more expensive, professional stack cutters.

Profitable even at low volumes

It cuts with great precision for a small investment. You get the same accuracy as from considerably more expensive machines. Profitable even at small volumes.

Easy to work with. The controls are at working height and a Plexiglas shield stops the sawdust. Easy to set up.

Easy to store. The portal-shaped design of steel, and three big castors give you a moblie stack cutter with a small footprint and that can easily be moved

Electrical system and motor

The electric motor is a, specially wound, motor with a rated output of 5kW (7 hp). While cutting, the motor load is 7-8 kW. It is protected by a temperature sensor.

This insulation class (54) means that the motor and the entire electrical system are unaffected by sprinkling water, thus capable of standing outdoors in the rain.

Sound level and ergonomics

The Stack Cutter 1500 is designed to provide the user with the best possible working conditions. The controls are positioned at work height and a Plexiglas sheet protects the operator against any flying chips. The sound level requires hearing protection.

Chip handling

The Stack Cutter works perfectly well without any sawdust transport equipment. However, since this will create considerable quantities of sawdust on the work site, a chip and sawdust extractor is recommended.

A simple accessory chip and sawdust extractor for the Stack Cutter 1500 is available to be fitted on the Stack Cutter support legs. Connecting the Stack Cutter to existing chip and sawdust evacuation systems works equally well.

Advantages

- You cut 1.5 m x 1.5 m stacks with a precision of +/-2 mm.

- ArmAiming arm for positioning the cut.

- Standard cutting equipment with 3/8” chain pitch means low operating costs.

- The ball-bearinged bar nose guide steers the bar in an exact line from the top down.

- Easy to use. The timber stack does not have to lie completely level before you make the cut.

- Stable steel structure gives straight cuts.

- Automatic oil pump.

- Max. power output: 10 kW.

- You adjust the guide bar and the vertical angle setting by a crank.

- Big castors make the stack cutter easy to move.

Advantages of vertical cutting

- Finer saw cuts

- You can cut larger timber stacks

- Low costs of cutting equipment

These videos illustrates an old model of Stackcutter PK1500. Modifications has been made on the new one.

![]() Latvia

Latvia